USE

Cardboard

Wood waste

PET bottles

FEATURES

Extremely durable direct drive system

Standard containers up to 36 m³

Optional pre-crushing feeding devices

Mobile and stationary variants available

CAPACITY

20 m³

24 m³

27 m³

30 m³

32 m³

35 m³

36 m³

ALL-ROUND SOLUTION FOR LARGE AMOUNTS OF WASTE

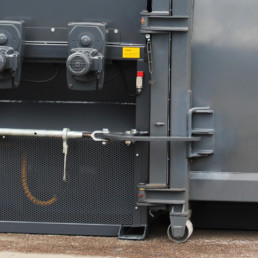

H&G screw compactors are shredding waste compactors designed to efficiently reduce the waste volume before it is compacted into a container. Their extremely high degree of compaction results in very high payloads for various materials. The robust compactors can be continuously loaded and support 24/7 heavy-duty usage.

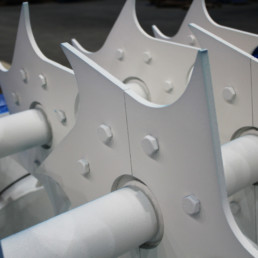

The strong build quality of the screw compactors contributes to extended service life. Instead of vulnerable chain-drive system traditionally used on screw compactors, they feature extremely durable electromechanical direct drive with automatic lubrication system.

With their comprehensive selection of separately driven feeding devices, the screw compactors are an all-round solution for various refuse materials. The compactors are available in both stationary and mobile variants. They can be supplied with a range of accessories e.g. bin lifts. Several standard container capacities ranging up to 35 m³ are available.

H&G screw compactors in use by Tamro logistics center

Tamro logistics center, which distributes medicines,

two Europress H&G screw waste compactors for cardboard.

Additional information

Infeed aperture W x L

1,400 x 1,200 mm

Infeed height (from a platform)

1,200 mm

Revolution speed

15 / 17* x/min

Capacity (cardboard)

100 m³ /h

Motor

11 / 15* kW

Power supply

400 V, 50 Hz, 3×C50 A

400 V, 50 Hz, 3×C63 A*

Blue color RAL 5017

Standard filling hopper

Control panel

Safety control panel

Fill level surveillance (pressure sensor)

Lift hook rear (container)(Stationary compactor)

Lift hook front / rear (Mobile compactor)

Front rollers on container (roll-off)(Stationary compactor)

Rear rollers on container (roll-off)

Container not present switch (safety limit)

Closing trap of the container (tarpaulin)(Stationary compactor)

Automatic central lubrication unit

Direct drive system

Custom RAL color

Guide rails

Additional controls e.g. emergency stops

Automatic emptying call function

Remote monitoring system

Custom filling hopper

2-phase discharge door opening mechanism

Long handle discharge door opening mechanism

Bin lift (integrated / stationary)

Lid opening system (hydraulic / electronic)

Feeding devices

Heavy duty variant

Double screw variant

Auto start system

15 kW power unit

Floating roof container 20-36 m²

Reserve container

H&G Stationary screw compactor

Length 1,550 mm

Width 1,310 mm

Height 1,740 mm

Weight 1,850 kg

Container 20 m³

Length 4,790 mm

Width 2,500 mm

Height 2,560 mm

Weight 2,300 kg

Container 24 m³

Length 5,530 mm

Width 2,500 mm

Height 2,560 mm

Weight 2,430 kg

Container 27 m³

Length 6,270 mm

Width 2,500 mm

Height 2,560 mm

Weight 2,680 kg

Container 30 m³

Length 6,400 mm

Width 2,500 mm

Height 2,560 mm

Weight 2,900 kg

Container 32 m³

Length 6,670 mm

Width 2,500 mm

Height 2,560 mm

Weight 3,000 kg

Container 35 m³

Length 6,675 mm

Width 2,500 mm

Height 3,070 mm

Weight 3,230 kg